Please watch our video above by clicking the play button.

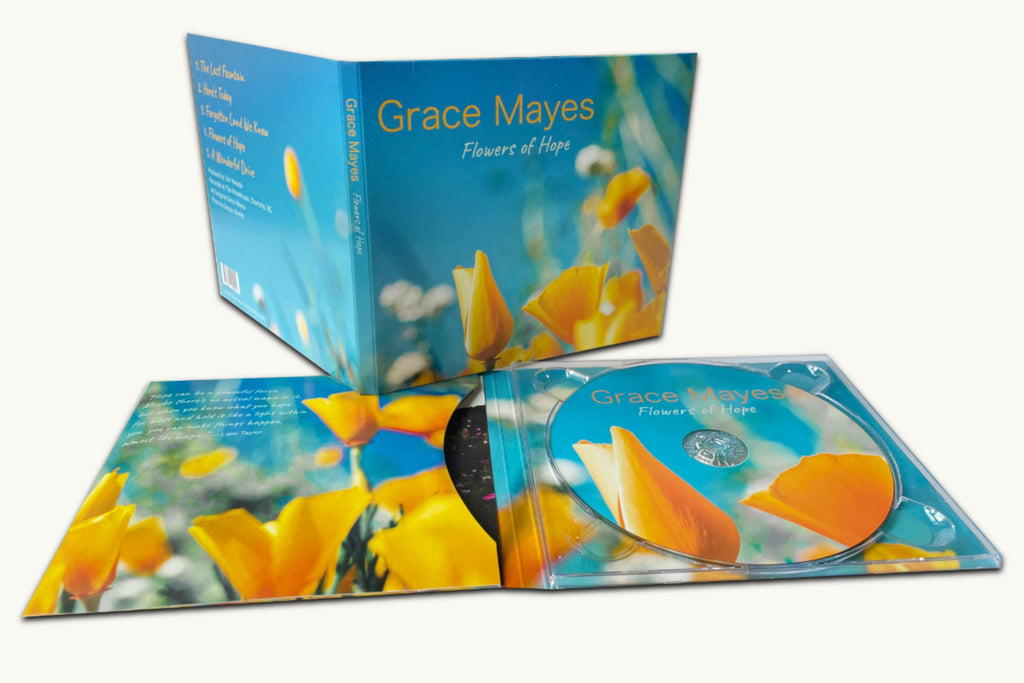

CDs in Digipack Lites™

Digipack Lite™ CD Packages Include

- Duplicated CD-Rs (less than 500 qty)

- Replicated CDs (more than 500 qty)

- Full color high resolution on-disc printing

- UV coated discs

- 4 or 6 panels

- 1 or 2 discs (4 panel only)

- Standard hard plastic trays or recycled flexi-trays

- Full color 4/4, digital digipack printing

- Printed using green friendly ink

- 16 pt FSC® certified partially recycled board stock

- Digital PDF proofs via email *

- Free barcode (optional)

- Packaged in USPS approved, clear re-sealable eco-bags

- Standard turnaround - 3-6 business days (12-14 business days for replication) **

- No sales tax or hidden fees :)

A CD can contain up to 79 minutes of audio.

* Up to three versions of graphics proofs included. $15 per additional beyond that. Only instant online proofs if using our online design tool.

** From artwork approval and all elements are received.

Video

Description

The Digipack Lite™ is a revolutionary new way to present CDs in a sleek, professional looking package at a very affordable price. Unlike standard digipacks it utilizes 4/4 printing technology, which allows for uninterrupted panoramic imagery on both the outside and inside of the package.

You have the choice between standard plastic digipack trays and our recycled flexi-trays, made from recycled water bottles.

How it differs from a standard digipack

A standard digipack is made by printing all 4 or 6 panels on the same side of a flat sheet of card stock, then die-cutting, folding and gluing it together. This makes the thickness of each panel twice as thick as the paper stock it is printed on. This also makes the inside of the spine white, as this needs to be cut off in order to fold it. The Digipack Lite™ is printed utilizing 4/4 (or double-sided) printing technology with full bleed, so when it is cut and folded there are no white borders or cutouts. (Unless the white is part of your design, of course. :-) This makes it lighter than a standard digipack which saves on shipping costs. The possibility of choosing our recycled flexi-trays makes it even lighter and more environmentally friendly.

How long will my job take?

Pre-production

Pre-production starts once you have placed an order and we have received all of your elements (audio, graphics...etc.) You will receive PDF proofs via email within 1-3 business days.

Production

Once you approve the proofs day zero of production time starts. Our estimated production time for duplication is 3-6 business days, and 12-15 business days for replicated jobs.

Transit

When production is complete and payment is received we will ship your order. Shipping time depends on which shipping method you choose and where we are shipping to.

Business days are Mon-Fri, not including holidays. These are estimated times and subject to change.

Templates

Cclick the links below to download .zip folders with templates in PDF and PSD versions.

CD Disc Print Templates

Choose Your Digipack Lite™ Template

- 4 Panel Digipack Lite™ Templates

- 4 Panel Digipack Lite™ with Pocket Templates

- 6 Panel Digipack Lite™ Templates

- 4 Panel 2 Tray Digipack Lite™ Templates

Optional Insert Templates

Duplication vs. Replication

Duplication (less than 500)

Duplicated discs (often called burned discs) are made by burning tiny holes in the dye layer of a recordable CD-R. It is the same process as when you burn a disc on your home computer. This is more cost-effective for small runs and takes much less time to produce. We use the highest quality CD-Rs on the market to ensure maximum quality and compatibility. There is not really any audible difference between replication and duplication. There might be a small percentage of older CD players or car stereos that is unable to play duplicated CDs. This is rare, but it does occasionally happen.

Replication (more than 500)

Replicated discs (often called pressed discs) are made by first creating a glass master, then stampers that make exact clones using high-tech injection-molding. A coat of reflective aluminum is added and finally it gets sealed with a protective coat of lacquer hardened by ultraviolet light. Because of this extensive set up process, it is common to require a minimum of 500 discs for replication.